What’s the impact of stress and strain in structural health monitoring?

by Eric Schmidt | Updated: 11/05/2024 | Comments: 3

How much is too much? Did you know that stress and strain can negatively impact your infrastructure? In this blog article, I’ll share a brief explanation of what you should know to protect the health of your critical structures.

Infrastructure across the US and around the world is aging, with each day bringing new wear and tear to roads, bridges, and buildings. Over time, this aging can lead to degradation, impacting safety and functionality. Structural health monitoring (SHM) plays a crucial role in preserving infrastructure and protecting public safety. By focusing on two fundamental measurements—stress and strain—SHM provides insights beyond what physical inspections alone can reveal, allowing you to understand and address underlying issues before they become critical.

What is stress?

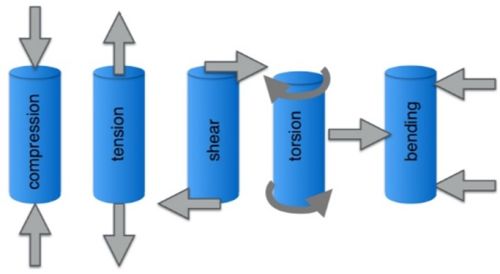

In structural terms, stress is the internal force exerted per unit area within a material. It occurs when external forces—loads, pressure, or temperature changes—are applied to a structure. Measured in Pascals (Pa) or pounds per square inch (psi), stress is generally categorized into five types, each affecting materials differently:

- Tensile stress – Stretching or pulling forces

- Compressive stress – Pushing or squeezing forces

- Shear stress – Forces causing sliding or tearing

- Torsional stress – Forces that twist a material

- Bending stress – A force that bends, involving three opposing forces, as shown below:

Calculating Stress

The formula for stress is straightforward:

What is strain?

Strain describes the amount of deformation or displacement a material experiences when stress is applied. Unlike stress, strain has no units; it’s the ratio of the change in length to the original length. Strain can be elastic (temporary and reversible) or plastic (permanent).

Calculating Strain

Strain is calculated using the following formula:

Why should you monitor stress and strain?

Monitoring stress and strain enables engineers to assess the structural integrity of buildings, bridges, dams, and other critical infrastructure. By measuring how structures respond to forces such as traffic, wind, or seismic activity, you can detect early signs of damage or deterioration, including cracks, deflections, or material fatigue.

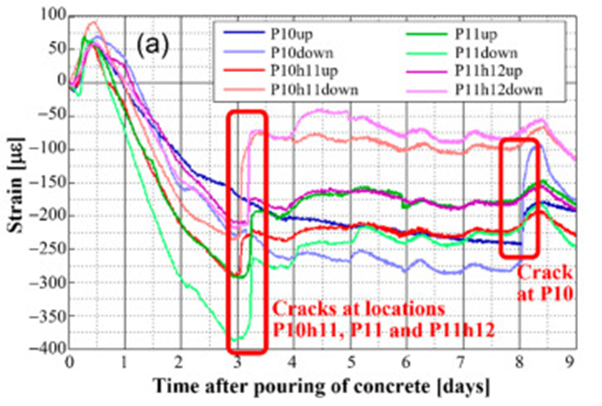

Strain serves as a key indicator of structural health. Its relationship with stress—illustrated through stress-strain curves for materials such as steel and concrete—helps you understand material performance under pressure. Strain data can also reveal cracks or fatigue, as shifts in these measurements often signal potential issues. For instance, a steady increase in strain followed by an abrupt drop in absolute strain typically indicates a crack has formed, providing temporary strain relief. (See the figure below.)

What measures strain?

In SHM, various sensors and systems measure stress and strain to detect changes in infrastructure. Here are some of the most widely used methods you should be aware of:

Foil-Bonded Strain Gauges

Foil-bonded strain gauges are some of the most popular tools for measuring strain. These sensors consist of a thin, conductive material bonded to a structure. As the structure deforms, the gauge deforms along with it, leading to a change in electrical resistance that reflects the strain experienced by the material. Strain gauges are particularly effective for monitoring localized deformations.

Vibrating Wire Strain Gauges

These gauges measure strain by detecting changes in the frequency of a wire under tension. Known for their durability, vibrating wire strain gauges are ideal for long-term monitoring in harsh environments, such as dams, tunnels, and underground structures.

Other Types of Strain Gauges

Several other technologies are available, including fiber optic strain gauges, which monitor reflections within a fiber optic cable or a Fiber Bragg Grating (FBG). Other, less common options include piezoresistive, MEMS, capacitive, and quartz crystal strain gauges, each offering unique advantages for specialized applications.

Interpreting Stress and Strain Data

To assess a structure's health, you must carefully interpret the raw data gathered from sensors. By analyzing stress and strain measurements, you can identify the following:

- Elastic and Plastic Deformation – It is critical to know whether the measured deformations are temporary and recoverable or if there is permanent damage that could weaken your structure.

- Crack Propagation – By monitoring areas with increasing strain, you can discover the growth of cracks or potential weaknesses in your structure.

- Overloading – When stress levels surpass a structure’s design capacity, you may need to take immediate action to prevent failure.

Systems such as Supervisory Control and Data Acquisition (SCADA) can work with data loggers to automate data collection and interpretation, providing you with real-time analysis and alerts when critical thresholds are reached.

Conclusion

A solid understanding of stress and strain is essential in SHM. These measurements reveal critical insights about the forces and deformations a structure experiences over time. With tools such as strain gauges and FBG sensors, you can monitor these metrics to help ensure the safety and durability of your vital infrastructure. When you integrate this data with modern interpretation systems, you are ensuring you have more resilient structures capable of standing up to the tests of time and nature.

Please reach out to our application engineers or sales team if you have questions on how to integrate strain gauges with your automated monitoring platforms. We’re here to help find the best solutions for your needs.

Eric Schmidt is an Application Engineer in the Infrastructure Group at Campbell Scientific, Inc. He works with customers on the technical aspect of building measurement systems; helps provide trainings for all of Campbell Scientific’s international offices; and attends conferences related to dams, mines, and geotechnology. He received his bachelor’s degree in biological engineering from Utah State University. In his spare time, he enjoys canyoneering and composing music.

Eric Schmidt is an Application Engineer in the Infrastructure Group at Campbell Scientific, Inc. He works with customers on the technical aspect of building measurement systems; helps provide trainings for all of Campbell Scientific’s international offices; and attends conferences related to dams, mines, and geotechnology. He received his bachelor’s degree in biological engineering from Utah State University. In his spare time, he enjoys canyoneering and composing music.

Comments

AndreaBR | 11/26/2024 at 02:20 PM

Nice article. Thanks Eric.

AndreaBR | 11/26/2024 at 02:22 PM

Eric, I would like to download this and oter articles you wrote. Is there a link for that? Thanks.

Robin D | 11/26/2024 at 02:25 PM

AndreaBR, we do not store blog articles as PDFs on our website for downloading. However, you can print the page as a PDF to obtain a copy.

Please log in or register to comment.