Overview

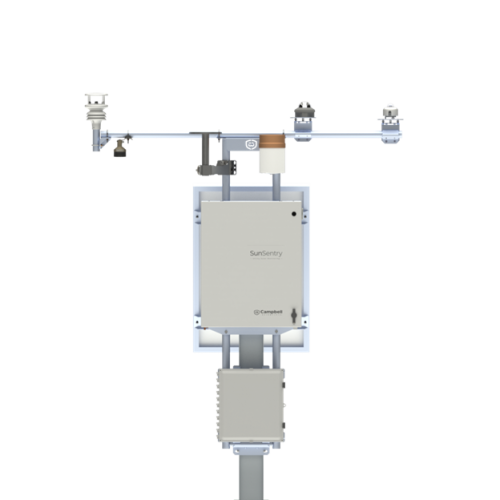

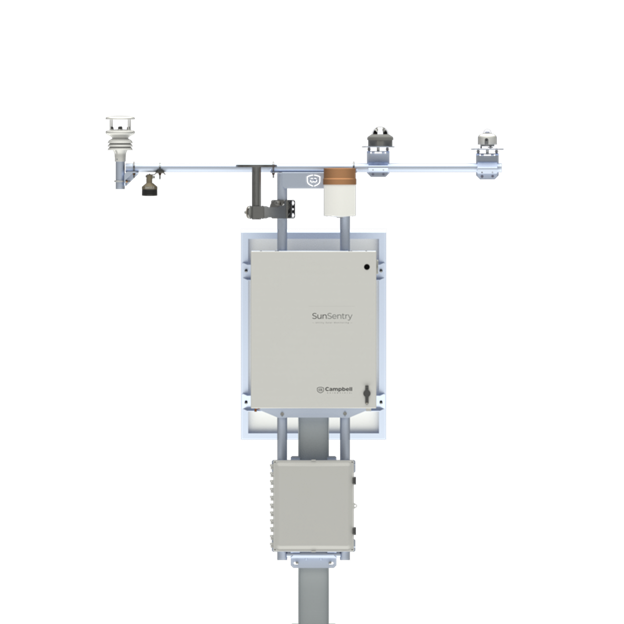

Campbell Scientific's SunSentry Operational Monitoring Station is purpose-built with the most up-to-date technology to be the easiest to use utility-scale operational meteorological (met) station on the market.

The SunSentry establishes a new chapter of met station design and ease of use. These stations are standardized, stocked, follow the industry requirements of IEC 61724-1:2021, and exceed IEC 61000-4-5 Class 4 surge immunity levels. Station installation is made easy via pile-mountable hardware and an all-new web user interface (UI).

Let us make ordering, receiving, installing, and commissioning met stations as simple as possible. Contact us to see how the SunSentry can fit your upcoming projects.

Read MoreBenefits and Features

- IEC 61724-1:2021-compliant station

- Compliance with California ISO or Alberta Electric System Operators (AESO) standards

- Modbus or DNP 3.0 communications to SCADA

- Quick installation and easy operation through web-based UI

- Rugged design

- Campbell Scientific sensor mounts for easy installation

Images

Detailed Description

Fully IEC 61724-1 Compliant

All required and optional meteorological parameters are supported within the SunSentry embedded web UI.

Advanced Surge and Data Protection

Industry best practices were followed in station topology recommendations as well as strategic placement of surge protection devices (SPD). These improvements are for maximum data availability while granting peace of mind for owners and developers. ISO 27001 guidance was also followed, providing an industry-first station for solar operational monitoring.

On-Time, FREE Delivery

Our project management team organizes the SunSentry delivery. Standardized and project-specific documentation packages are available. Stations are stocked and available with short lead times or can be ordered early and delivered to your site when they are required. Each SunSentry station is packaged on its own pallet, making on-site distribution straightforward for field personnel.

Campbell Scientific has found that moving equipment out the door quickly saves us and our customers time and money. We have established relationships with all major carriers. To further shorten lead times, Campbell Scientific absorbs the shipping costs of SunSentry stations.

Note: Terms and conditions apply, including geographic availability.

Turn-Key Solution

Campbell Scientific tests and documents each complete system at our factory. The sensors are pre-labeled before shipping for easy on-site installation. Your technicians can provide us with network information for configuration prior to shipping or they can enter the information on-site using the embedded web UI.

Unparalleled Value

The SunSentry—with its UI, extensive sensor support, and robust, forward-looking hardware design—comprises met stations that are built to last each project's lifetime, evolving with changing requirements as needed. The applicable sensors collect data that allow users to glean the most value from the SunSentry.

Legendary Campbell Scientific Quality

Campbell Scientific has been providing robust hardware solutions for the most challenging meteorological settings for more than 50 years. The SunSentry leverages this expertise and now uses Campbell Scientific's proven, reliable data logger line-up for the solar energy market as a cost-effective system with a standard design.

Network Resiliency

The SunSentry is designed to isolate and protect the most valuable sensors in the most vulnerable locations. This ensures the highest data availability for sensor data to the met station. Simultaneous Modbus TCP, DNP3, and FTP data collection is available for the end user to collect data from the met stations.

Pile Mountable

Stations are designed to mount to industry-standard-driven piles without the need for drilling. SunSentry stations are designed to be installed by a single technician in a single day with common hand tools.

Standardized but Still Versatile

Built around IEC 61724-1:2021 and taking cues from many industry system requirements, the SunSentry is capable of supporting double the required parameters, making it the most scalable option on the market.

Compatibility

Supported Sensors in the SunSentry Web UI

| Measurement/Parameter | Sensors | Total Quantity Available/Station |

|---|---|---|

| GHI | MS-80SH, SR30, SR300, SMP10, SMP12 | 2 |

| POA | MS-80SH, SR30, SR300, SMP10, SMP12 | 2 |

| RPOA | RC22, MS-80SH, SR30, SR300, SMP10, SMP12, SR05, MS-40S, SI-RS485TC-T-MB | 6 |

| Horizontal Albedo | MS-80SH, SR30, SR300, SMP10, SMP12, SR05, MS-40S | 2 (albedo measurements) |

| DHI | SPN1, Shaded DHI Sensor (same as supported GHI measurements)* | 1 |

| Soiling | DustVue™, DustIQ, Mars, RC22 Comparison, RDE300i (limited configurations), FracSun* | 2 |

| Back-of-Module Temperature | CS241DM | 6 |

| Ambient Temperature | ClimaVue™40, MetSens500, LufftWS500, WS601, HygroVue™*, 107 Probe* | 2 |

| Relative Humidity | ClimaVue 40, MetSens500, LufftWS500, WS601, HygroVue* | 2 |

| Atmospheric Pressure | ClimaVue 40, MetSens500, LufftWS500, WS601, BaroVue™10* | 2 |

| Wind Speed | ClimaVue 40, MetSens500, LufftWS500, WS601, 05103* | 2 |

| Wind Direction | ClimaVue 40, MetSens500, LufftWS500, WS601, 05103* | 2 |

| Rainfall | ClimaVue 40, TE525 , RainVue™10*, RainVue 20*, 52202* | 2 |

| Lightning Detection | ClimaVue 40 | 2 |

| Hail | HDI | 2 |

| Snow Depth | SnowVue™10 | 2 |

| Visibility and Present Weather | CS125 | 1 |

*Support coming soon

Specifications

| Standards Used |

|

Documents

Technical Papers

Miscellaneous

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences